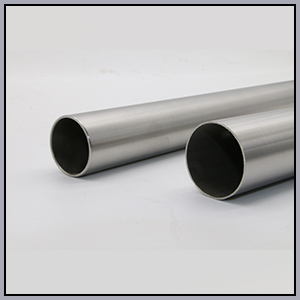

| Porduct | Zirconium Tube-pipe |

|---|---|

| Grade | UNS R60702 |

| Standard | ASTM B523/B523M-07 |

| Outer diameter | 0.315 to 5.99” (8mm to 152 mm ) |

| Wall thickness | 0.02 to 0.59” (0.5mm to 15mm) |

| Length | up to 354 ”(9000mm) |

| Surface | Polished or according to customer’s requirement |

The zirconium tube (Zirconium Tube) has strong corrosion resistance due to the formation of a stable oxide film and is not affected by acids (except HF) and alkalis. Because of its corrosion resistance, zirconium tubes are widely used in the chemical industry where corrosive agents are used. Because of its excellent high-temperature performance, coupled with its low neutron absorption, it is used to build nuclear reactors.

Chemical composition

| content % | |||||||||||

| Grade | Main ingredient | Impurities Max | |||||||||

| Zr+Hf | Hf | Fe+Cr | O | H | N | C | Nb | ||||

| R60702 | ≥99.0 | 4.5 | 0.2 | 0.11-0.15 | 0.005 | 0.015 | 0.03 | / | |||

Mechanical properties

| Grades | Tensile strength(MPa) | Yield strength(MPa) | Elongation (%) |

| R60702 | 380 | 205 | 16 |

Tests

Tests are done according to customers’ quality requirements

- Chemistry test

- Reverse flattening test

- Flare test

- Pneumatic test

- Hydrostatic test

- Eddy current test

- Ultrasonic test

- Tension test

Inspection

We ensure the highest quality zirconium tube while we also offer the best quality customer service, and fast turn-around orders with no limitations, all at a reasonable price. pursuit of perfection to every detail does not stop until our customer is satisfied.