| Standard | GB/T 3622/ASTM B265/ASME SB265 | |||||||

|---|---|---|---|---|---|---|---|---|

| Grade | TA1、TA2、TA3、TA4、TA4G、TA9、TA10、GR1、GR2、GR3、GR4、GR5、GR7、GR11、GR12 | |||||||

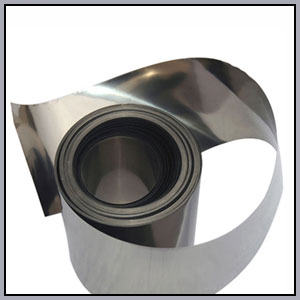

| Thickness | 0.01mm~0.5mm | |||||||

| Width | 0.05~0.99 (10 mm~600 mm) / 1.0~6.0 (≤1500 mm) | |||||||

| Technique | Cold rolling & hot rolling | |||||||

| Surface | Bright / matte | |||||||

| Application | Metallurgy, electronics, chemical, petroleum, pharmaceutical, etc. | |||||||

Chemical Composition(ASTM B265)

| content % | ||||||||||||

| Grade | Main ingredient | Impurities Max | ||||||||||

| Ti | C | H | N | O | Fe | Al | V | Pd | Mo | Ni | ||

| Gr.1 | Surplus | 0.08 | 0.015 | 0.03 | 0.18 | 0.2 | / | / | / | / | / | |

| Gr.2 | Surplus | 0.08 | 0.015 | 0.03 | 0.25 | 0.3 | / | / | / | / | / | |

| Gr.3 | Surplus | 0.08 | 0.015 | 0.05 | 0.4 | 0.5 | / | / | / | / | / | |

| Gr.4 | Surplus | 0.08 | 0.015 | 0.05 | 0.4 | 0.5 | / | / | / | / | / | |

| Gr.5 | Surplus | 0.08 | 0.015 | 0.05 | 0.2 | 0.4 | 5.5-6.75 | 3.5-4.5 | / | / | / | |

| Gr.7 | Surplus | 0.08 | 0.015 | 0.03 | 0.25 | 0.3 | / | / | 0.12-0.25 | / | / | |

| Gr.9 | Surplus | 0.08 | 0.015 | 0.03 | 0.15 | 0.25 | 2.5-3.5 | 2.0-3.0 | / | / | / | |

| Gr.12 | Surplus | 0.08 | 0.015 | 0.03 | 0.25 | 0.3 | / | / | / | 0.2-0.4 | 0.6-0.9 | |

Titanium Foil Properties

| Grade | Status | Tensile Strength | Yield Strength | Elongation | Area of Reduction | ||||

|---|---|---|---|---|---|---|---|---|---|

| Ksi | Mpa | Ksi | Mpa | % | |||||

| Gr.1 | Annealed | 35 | 240 | 25 | 170 | 24 | 30 | ||

| Gr.2 | 50 | 345 | 40 | 275 | 20 | 30 | |||

| Gr.3 | 65 | 450 | 55 | 380 | 18 | 30 | |||

| Gr.4 | 80 | 550 | 70 | 483 | 15 | 25 | |||

Titanium Foil Features

Corrosion resistance

Low modulus of elasticity

Good heat-exchanger performance

Suction performance

Bear high & low temperature

Non-magnetic and non-toxic

Titanium Foil Detection

We perform a visual inspection to check the surface quality and ensure no flaws, blackspots, and any other defects.

We also do chemical composition detection, making sure all chemical components meet demands.

Mechanical features testing, making sure all-titanium foils have satisfying mechanical features before delivery.