Clad components, particularly titanium clad, are increasingly used in industry, because of their resistance to chemical attack and of their mechanical properties.

Materials:Titanium, SS, Steel, Nickel, Cu, Al, Ni, Zr, Ta, Cs, etc.

Supply state: R state, Y state, BM state or BR state

Manufacturing method: hot extrusion, hot extrusion + stretching, explosion, explosion + rolling

Section shape: square, rectangle, circle, drum, flat

Surface state: hot extrusion surface, cold working surface, explosive composite annealing surface, explosive composite hot working surface

Titanium-copper composite rod, also known as titanium-clad copper, is a titanium layer coated with a certain thickness on the copper rod, which is the main component of the metal anode. It integrates the excellent electrical conductivity of copper and the excellent corrosion resistance of titanium and is mainly used in electrolysis, electroplating, hydrometallurgy, and metal anode electrolytic cells under strong corrosion conditions. On the other hand, it exerts the corrosion resistance of the coating material, which is a high-quality electrode. The composite rod produced by TFM Metals has a composite strength of 135Mpa and a tensile shear strength of 180-260Mpa, which has good electrical conductivity. , The micro-resistance of the composite rod is 7.77×10-6Ω, which can greatly reduce the pollution of electrolyte and electroplating solution, save energy consumption and improve the environment. It is an energy-saving and environmentally friendly electrode material. According to user requirements, we can produce round, drum, square, flat and other composite rods of different specifications, and can also perform bending and group welding of different shapes.

| Product | Clad Metal (“CM”) | Base Metal (“BM”) | Dimension(mm) | Standards | Applied Industry |

| Ti/Steel | Titanium (Gr.2, Gr.3, Gr.7, Gr.12, etc) | Carbon Steel & its forging | (CM TK)1-20/(BM TK)2-200*W3000*L6000 | GB8547-2006 ASTM B898 JIS G3603 |

Petrochemical, Vacuum Salt, Chlor-alkali Industry, Power-station FGD, Hydrometallurgy, Electroplating, etc. |

| Ti/Stainless steel(SS) | Titanium (Gr.2, Gr.3, Gr.7,Gr.12 etc) | SS & its forging | (CM TK)1-20/(BM TK)2-200*W3000*L6000 | GB8546-2007 Agreement |

Petrochemical, Chlor-alkali Industry, Aerospace Engineering, Cryogenic Engineering, Food Industry, Pharmacy, etc. |

| Ti/Cu | Titanium (Gr.2, Gr.3, Gr.7, Gr.12, etc) | C11000, C12100, C26800, etc. | (CM TK)1-20/(BM TK)2-100*W2000*L4000 | Q/XB1506-94 Agreement |

Electric Power, Electrolysis industry, Kitchen, Hydrometallurgy, Etc. |

| Ti/Al | Titanium (Gr.2, Gr.3, Gr.7, Gr.12, etc) | 1199, 1050, 2124, 4130 | (CM TK)1-20/(BM TK)2-50*W1500*L4000 | Agreement | Aerospace, Kitchen, Chemical Industry, Naval vessels, Special solder, etc. |

| Ti/Ni | Titanium (Gr.2, Gr.3, Gr.7, Gr.12, etc) | N02201 N02200 & Nickel Alloy | (CM TK)1-20/(BM TK)2-50*W2000*L4000 | Agreement | Hydrometallurgy |

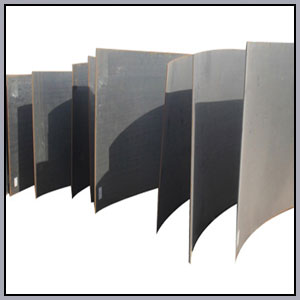

Multilayer Clad Plate

| Multilayer Clad Plate | Inside Metal (IM) | Outside Metal (OM) | Dim. Range (mm) | Standards | Applied Industry |

| Ti/CS/Ti | CS & its forging | Gr.2, Gr.3, Gr.7, Gr.12 | (OMK)1-10/(IM)1-200/(OM)1-10*~ | Agreement | Petrochemical, Chemical Industry, Pharmacy, etc. |

| Cu/Ti/Cu | Gr.2, Gr.3, Gr.7, Gr.12 | C11000, C12100, C26800 | (OM)0.5-10/(IM)1-10/(OM)0.5-10*~ | Agreement | |

| Ti/CS/SS | CS & its forging | Gr.2, Gr.3, Gr.7, Gr.12 SS & its forging | (OM)1-10/(IM)1-200/(OM)1-10*2500*4000 | Agreement | |

| SS/CS/SS | CS & its forging | SS & its forging | (OM) 1-20/(IM)10-200/(OM)1-20 *4000*8000 |

Agreement | |

| Al/Ti/CS | Gr.2, Gr.3, Gr.7, Gr.12 | 1199, 1050,2124, 413.0/ CS & its forging | (OM)1-20/(IM)1-5/(OM)8-200*1500*4000 | Agreement | |

| Cu/Al/Cu | 1199, 1050, 2124, 413.0 etc. | C11000, C12100, C26800, | (OM)0.5-20/(IM)0.5-100/(OM)0.5-20*~ | Agreement | |

| Al/Ti/Cu | Gr.2, Gr.3, Gr.7,Gr.12 | 1199,1050,2124, 413.0 ./C11000,C12100, C26800, |

(OM)1-10/(IM)1-5/(OM)1-100*~ | Agreement |