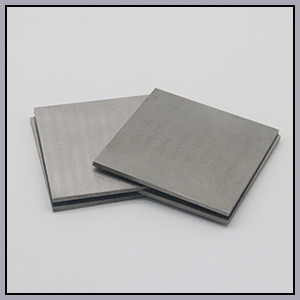

| Porduct | Tantalum_Sheet_plate |

|---|---|

| Standard | ASTM B708 |

| Purity | 99.95%,99.99% |

| Thickness | 0.5mm-50mm |

| Width | 5-500mm |

| length | As Your Required |

| Substrate | RO5200,RO5400,RO5252,RO5255 |

Almost all tantalum plates are cold worked. Generally, starting from a tantalum ingot of 150 to 300 mm, cold forging produces a slab about 80 to 100 mm thick, and then cold rolling from this slab, the compression rate can be above 95%. In commercial production, slabs are usually rolled with two-rolling mills or four-rolling mills to form 6.3-12mm thick plates with a width of 510-1020mm. Typical rolling is carried out at or near room temperature to prevent the formation of oxides on the surface. When hot rolling is required, due to recrystallization, the temperature rises to 1000°C and an intense oxidation reaction occurs.

Almost all thick plates are heat-treated and annealed in a vacuum. Since there is no phase transition, the rate of heating and cooling is not important. It is further rolled with an ordinary rolling mill, and at this time, 4 rolling mills and multiple rolling mills are generally used. Since tantalum is very soft, care should be taken to prevent scratches during processing and transportation.

- Tantalum has good plasticity and is relatively stable at high temperatures, and can absorb and hold gas.

- Is acid-resistant and is a biocompatible material.

- Tantalum is an indispensable material for making cemented carbide.

chemical composition:

| content % | |||||||||||||

| Grade | Main ingredient | Impurities Max | |||||||||||

| Ta | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | ||

| Ta1 | Surplus | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.01 | |

| Ta2 | Surplus | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.01 | |

| Ta2.5W | Surplus | 0.005 | 0.005 | 0.002 | 3.0 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 | |

| Ta10W | Surplus | 0.005 | 0.005 | 0.002 | 11 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 | |

Mechanical properties:

| Status | tensile strength(MPa) | Elongation (%) |

| M | 300-750 | 10-30 |

| Y2 | 750-1250 | 1-6 |

| Y | >1250 | 1-5 |

Service:

TFMMetal can customize according to the drawings provided by customers.

We will provide customers with a tantalum sheet that meets the standards. If necessary, we can provide third-party test reports, including chemical composition and physical properties. It can also meet the special requirements of customers.