| Parameters | Description |

|---|---|

| Material | Titanium and titanium alloy |

| Filtration precision um | 0.5-50 |

| Poriness | 20-50% |

| Compressive strength | 2-3Mpa |

| Permitted work temperature in the air | 300℃ |

| Application | Mainly used in separation and filtration petrochemicals, liquid drug manufacturing, medical equipment, and other fields. |

Main performance

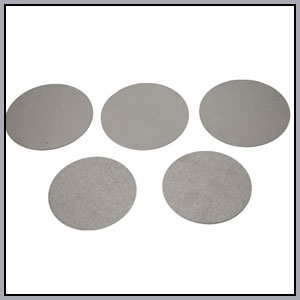

Titanium powder sintered filter material (including tube type and plate type) is a microfilter element made of industrial high-purity titanium powder (99.7%) after sieving and molding. Therefore, the titanium powder sintered filter material has unique and excellent properties due to its high-tech material composition and special molding process:

- Uniform pore size, stable pore shape, and high separation efficiency.

- High porosity, low filtration resistance, and high penetration efficiency.

- High-temperature resistance can be used normally below 250℃.

- Good chemical stability, acid and alkali corrosion resistance (PH2-12), and oxidation resistance.

- No particles fall off, do not cause secondary pollution of the original solution, and meet the requirements of food hygiene and pharmaceutical GMP.

- Good mechanical properties, low-pressure difference, large flow rate, pressure filtration, suction filtration, and simple operation.

- It has a strong anti-microbial ability and does not interact with microorganisms.

- It can be regenerated online, is easy to clean, and has a long service life (usually several times that of the membrane filter element)

- The forming process is good, and the overall length without welding can reach 1200 mm.

- It is non-magnetic and non-toxic and has good compatibility with human tissue and blood. It is widely used in the pharmaceutical industry, food industry, and water treatment industry.

Application fields of the titanium filter element

With its unique performance, the titanium filter element can be widely used in the pharmaceutical industry, water treatment industry, food industry, bioengineering, chemical industry, petrochemical industry, metallurgical industry, and gas purification. It is a new type of filter material with broad development prospects. Typical uses include:

- Decarbonization filtration in the concentrated distribution of large infusions, small injections, eye drops, and oral liquids in the pharmaceutical industry and security filtration before terminal filtration in the diluted distribution.

- Impurity removal filtration, decarbonization filtration, and fine filtration of materials in the production process of raw materials.

- Ultrafiltration of water treatment, security filtration of RO and EDI systems, filtration after odor sterilization, and ozone aeration.

- Clarification and filtration of beverages, fruit juice, liquor, beer, vegetable oil, mineral water, soy sauce, and vinegar in food and beverage processing.

- Decarbonization filtration and precision filtration of liquid products, liquid raw materials, and pharmaceutical intermediates in the chemical industry, filtration and recovery of ultra-fine crystals and catalysts, precision filtration after resin adsorption, and impurity removal and filtration of system heat transfer oil and materials, catalytic gas purification, etc.

- Oilfield reinjection water filtration, security filtration of reverse osmosis in the field of seawater desalination.

- High-temperature decarbonization and dewhitening filtration in the dye industry.

- Steam, compressed air, and catalyst filtration in gas purification.