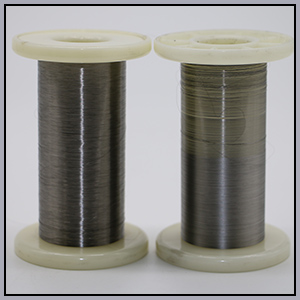

| Porduct | Molybdenum Wire |

|---|---|

| Standard | ASTM B387 |

| Purity | Mo >99.95% |

| Density | 10.2g/cc |

| Surface | Black, alkali washing |

| Diameter | 0.06-0.5mm |

| Tolerance | Customized |

The melting point of molybdenum is 2620°C. Because of the strong bonding force between atoms, it has high strength at room temperature and high temperature. It has a small expansion coefficient, high electrical conductivity, and good thermal conductivity. It does not react with alkali solutions at room temperature, and only dissolves in nitric acid or concentrated sulfuric acid. It is also suitable and stable for most liquid metals, non-metal slags, and molten glass. Therefore, molybdenum and its alloys have a wide range of applications and outstanding prospects in important parts of metallurgy, agriculture, the electrical, chemical industry, environmental protection, and aerospace.

Molybdenum wire surface condition molding process: drawing, forging, polishing.

Types and uses of molybdenum wire

- Pure molybdenum wire GMPM: used for winding-core wires, brackets, lead wires, heating elements, molybdenum foil strips, wire cutting, auto parts spraying, etc.

- Lanthanum molybdenum wire GMHI-M: used for winding-core wire glass sealing parts, molybdenum foil tape, furnace heating materials, wire cutting high-temperature components, etc.

- Yttrium molybdenum wire GMHYM: used for brackets, lead wires, electronic tube reeds, grids, furnace heating materials, and high-temperature components.

- Molybdenum wire GMPM.-1, GMHI.M.-2 for wire cutting is used for cutting various non-ferrous metals, steel, and magnetic materials. It has the characteristics of high strength, good discharge performance, high surface finish, low cutting speed, and long life.

The characteristics of molybdenum wire as electrode wire

- Ultra-high tensile strength;

- The surface finish is high, the stability is good, and the cutting precision is high;

- The elongation is small, and the tightness is small;

- The crimp rate is large, the wire diameter is consistent, the wire is not easy to break, and the life is long;

- It can increase the high-frequency power and improve the roughing efficiency;

- With accurate measurement, vacuum packaging prevents oxidation and mildew and can be stored for a long time.

Properties

- High Melting Point: 2625°C (4760 °F)

- High Density: 10.3 g/cm³

- High Tensile Strength

- High Absorption Capacity

- High Elastic Modulus

- Low Coefficient of Thermal Expansion

- Low Vapor Pressure

- Low Electrical Resistivity