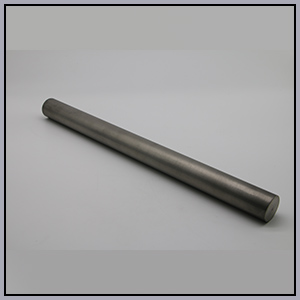

| Porduct | Molybdenum Rod-bar |

|---|---|

| Standard | ASTM B387 |

| Purity | >99.95% |

| Density: | >10.2g/cc |

| Diameter | 2.0-100mm |

| Length | max.1500mm |

| Surface | Black, Ground, Polished, Chemical cleaned |

Molybdenum’s high purity, high-temperature resistance, and low vapor pressure characteristics make it often used to make heating elements and structural materials for high-temperature furnaces. In the production process of tungsten molybdenum and cemented carbide, most of them use molybdenum wire heating to make restorations. Furnace and sintering furnace, part of the iron products are continuously sintered with a molybdenum rod heating row as the heating element, and the molybdenum rod heating row is hung on both sides of the furnace by molybdenum hooks. This type of furnace is generally a restorative atmosphere or a non-oxidizing atmosphere. Molybdenum wire can be used close to the melting point in the process of differentiation, and it can be used up to 2000 ℃ in nitrogen. When the temperature is higher than 1700℃, TZM alloy or molybdenum-lanthanum alloy with higher recrystallization temperature and better strength can be used as a heating element.

Molybdenum rods have a high melting point, good thermal conductivity, and low thermal expansion. They can be used to manufacture electric vacuum devices and electric light source parts, as well as high-temperature heating elements, high-temperature structural parts, electrodes, etc.

Production and processing procedures: forming-sintering-hanging forging-machining

Product category

Pure molybdenum rod: the content of molybdenum is greater than 99.95%;

High-temperature molybdenum rods (molybdenum-lanthanum alloy rods): containing 0.4~1.2% lanthanum, and the molybdenum content is the balance excluding impurities;

TZM rod: Mo-0.5Ti-0.07 ~ 0.12Zr-0.01 ~ 0.04C;

Molybdenum rods are divided into forged molybdenum rods and polished molybdenum rods. The surface of forged molybdenum rods is allowed to have a slight oxide film and forging hammer marks; the surface of polished molybdenum rods shows metallic luster without oxidation; the two surfaces have no defects, such as Layers, cracks, burrs, and vertical cracks, etc.

Surface features

- The surface of the sintered molybdenum rod is silver-gray metallic luster;

- There is a layer of oxide on the surface of the forged molybdenum rod, and the surface is black;

- Polished molybdenum rod with a silver-gray metallic luster.

Method of removing surface oxides

- Molybdenum products are easy to oxidize. When removing heavy oxides, they can be treated with a strong acid (fluoric acid, nitric acid, hydrochloric acid, etc.)

- For mild oxides, use an abrasive cleaning agent, wipe it with a soft cloth or sponge, and then wash it off with warm water. The washed molybdenum products will lose their metallic luster.

Application

- Used to manufacture electric vacuum devices and electric light source parts;

- Suitable for processing ion-implanted parts;

- Used as the high-temperature heating element and high-temperature structural parts;

- Used as an electrode